Analysis on the pattern and prospects of the recycling industry of lithium batteries

With the global oil shortage, rising oil prices, increasing pressure on environmental protection and the adjustment of domestic energy structure, new energy vehicles have gradually become the development trend of the automobile industry in China and the world. Increasing policy preference, large-scale auto companies' aggressive layout, and increasing consumer awareness of environmental protection have led to the rapid expansion of my country's new energy vehicle market. In 2009, the intensive support policy opened a fast track for the growth of my country's new energy vehicles. In 2011, the industry entered the industrialization stage. In 2014, my country's new energy vehicle market showed a blowout trend, with production and sales increasing more than three times year-on-year.

New energy vehicles are divided into three sectors: upstream raw materials, midstream parts and components, and downstream applications. It can be found that the batteries, motors, and electronic controls in the midstream field (that is, the 'three powers' we often call) constitute the core of new energy vehicles. Different from traditional engines, they form an 'electric' powertrain. Lithium batteries are New energy vehicles play an important role in the production process. The production and sales of domestic new energy vehicles have repeatedly hit record highs, which has brought explosive growth in the power lithium battery industry.

Lithium electric vehicles used in China’s new energy vehicles, due to technical and frequency limitations, are designed to have an effective service life of about 3 years, and they need to be replaced after 3 years. . Ruixin Consulting believes that 2018 is the first year of lithium battery recycling for new energy vehicles, and my country's new energy vehicle power batteries will enter a large-scale retirement stage.

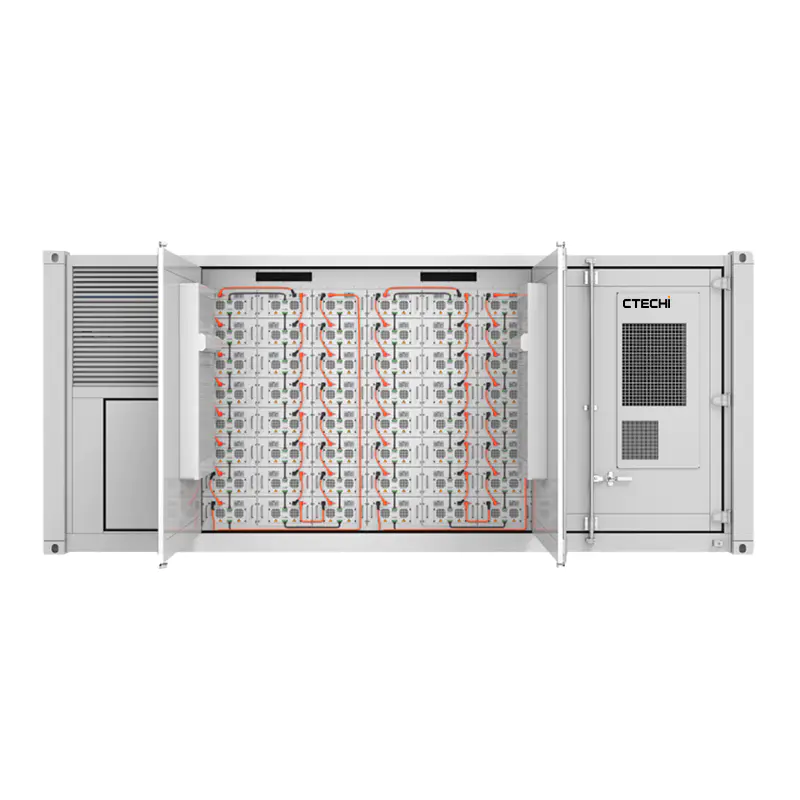

There are two major types of disposal methods in the lithium battery industry after decommissioning: reuse and recycling. Reuse is further divided into replacement use of new energy vehicles with lower energy consumption, use of large-scale energy storage equipment, and use of other low-energy-consumption lithium batteries; resource recycling is the dismantling and recycling of lithium batteries.

The reuse and recycling of lithium batteries after decommissioning will bring huge economic income to the new energy market. According to the new energy vehicle production and sales data of the China Automobile Association at the end of 2017 It is estimated that the decommissioned power lithium battery reached 11.09GWh in 2018, and the reuse and recycling of resources corresponds to a market space of 6.591 billion. Among them, the recycling income of lithium batteries is estimated to be 44,200 yuan/ton, and there will be a tens of billions of market for lithium batteries in the future.

The recycling of lithium batteries can be described as the right time. At the end of 2017, the Ministry of Finance ended the three-year subsidy policy for new energy vehicles, and the new energy vehicle industry returned to normal operations. On the track, improving technical content, extending battery life, and reducing costs and increasing efficiency will become important follow-up directions. Ruixin Zhicheng experts believe that with the gradual increase in the price of lithium battery raw materials, the recycling of lithium batteries will effectively solve the problem of excessive lithium battery manufacturing costs.

After years of use and charging of lithium batteries, the internal structure has changed. With the increase of the age, the burning risk and leakage risk of lithium batteries increase year by year, and the recycling of lithium batteries will Effectively solve problems such as deflagration and environmental pollution. At the same time, for the government, avoiding environmental pollution and resource waste is the significance of lithium battery recycling. For the industry, lithium battery recycling is an indispensable part of the complete life cycle of the new energy automobile industry, constituting a closed loop of the industrial chain from production, sales, operation, after-sales service to recycling. For battery manufacturers, the recycling of power batteries contains business opportunities and has a positive impact on the company's social image.

Before the suspension of new energy vehicle subsidies at the end of 2017, a number of new energy vehicle recycling policies were issued at the national level. In the future, the government will be responsible for the new energy vehicle recycling industry. The biggest supporter, the industry will also have better development.

With the popularity of new energy vehicles in China, the increasing pressure on environmental protection, the continuous increase in the price of lithium battery raw materials, the breakthroughs in reuse and resource recovery technology, Rui Xinzhicheng believes that the total lithium battery recycling market from 2018 to 2023 is about 13 billion. 2018 will be a harvest year for lithium battery recycling, and it is also a crucial year. Reuse and resource dismantling will be The price of the lithium battery raw material market to achieve a 'balance of supply and demand' market will also tend to be rational; at the same time, it can also effectively alleviate the cost pressure caused by the Ministry of Finance's suspension of new energy vehicle subsidies.